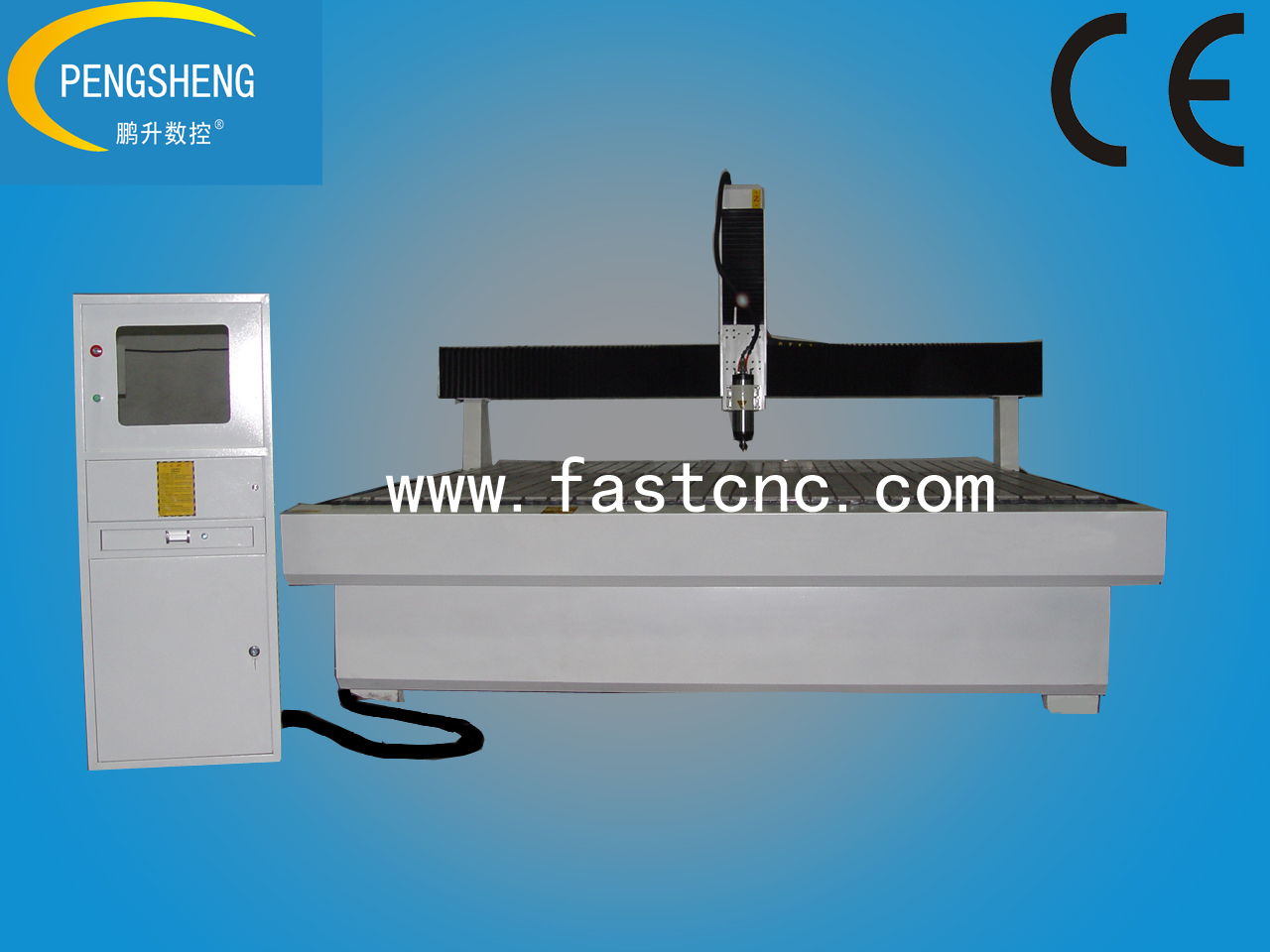

Feature:

1. Lathe bed is welded with thick square tube and is processed by high temperature tempering treatment,good

rigidity and heavy loading.

2. Three axes adopt imported high precision Taiwan square orbit;X and Y axes adopt rack and pinion transmission,

fast working,high efficiency and low cost;Z axis adopts Germany-made ball screw,with high precision and long life time.

3. Well compatibility:CAD/CAM designing software e.g.

Type3/Artcam/Castmate/Wentai etc.

4. Has the function of re-carving after break point and power failure.

5. Has the function of forecasting process time.

6. Adopting advanced DSP system with USB connection,operated with the handle,convenient operation.Our

engaber can completely work off-line and do not take any computer resources.

7. Auto oiling system

8. Adopt imported linear square orbit,highprecision,heavy loading and long lifetime.

9. High precision,the curving and linear speeds are consistent.Adopting execellent parts makes the fault rate

to be the lowest one.

Technical Parameter:

|

Model |

PC-1530PH |

It can be customized |

|

X.Y working area |

1500mm*3000mm |

|

|

Z working area |

500mm |

|

|

Table size |

2150mm*3650mm |

|

|

Resolution |

0.02mm |

|

|

X,Y structure |

Rack and pinion transmission |

|

|

Z structure |

Germany-made ball screw |

|

|

Max speed |

30m/min |

|

|

Spindle power |

8.0kw |

|

|

Spindle rotating speed |

0-24000r/min |

|

|

Cooling mode |

Water cooling |

|

|

Working voltage |

AC380V/50/60 Hz ,3PH |

|

|

Drive Motor |

Stepper |

|

|

Command |

G code*.u00*.mmg*plt |

|

|

Operating system |

DSP(with separate operation cabinet) |

|

|

Interface |

USB |

|

|

Flash Memory |

128M |

|

|

Diameter of cutter |

3.175-12.7 |

|

|

Net weight |

2000kg |

|

Applicable Industries:

GRG,GRC, Gypsum fabrication project indoors or outdoors.

Applicable Materials:

Wood,soft metal,PVC,plastic,MDF,aluminium,etc.